In May, I wrote an article about building a preamplifier for a moving coil phono cartridge. At the time, I had not too long ago changed my ageing transferring magnet cartridge with a pleasant new transferring coil cartridge, and my phono preamplifier didn’t present sufficient voltage acquire to straight use the brand new cartridge. So, after quite a lot of consideration, I made a decision to construct the Muffsy moving coil preamplifier kit.

It was the primary time in years that I’d constructed one thing electrical, and I actually loved getting out the soldering iron and making this unit. I additionally appreciated that the Muffsy’s design is open source. The on-line directions are glorious. The man behind Muffsy, Håvard Skrodahl, is most sort and useful, which is nice when you’ve messed one thing up and also you’re undecided what to do subsequent. The equipment’s value is most affordable. And the efficiency is exemplary.

But what in case you have a pleasant turntable and transferring magnet cartridge however no phono preamplifier in your receiver? Maybe you’re a kind of 67,000 people in the USA who bought a turntable in 2017? Or you may have a pair of powered audio system that you simply’d prefer to hook as much as the turntable, or perhaps a headphone amplifier? In that case, you is perhaps looking for a phono preamplifier, and one choice could be to construct the Muffsy phono preamplifier kit. Of course, when you’re actually useful you should use the circuit schematics and roll your personal from the bottom up, however the boards that Muffsy provides are of exceptionally prime quality, so it’s arduous not to decide on that choice.

In any case, I didn’t want a brand new phono preamplifier, however Håvard had simply launched a brand new model—the PP-Four—and invited me to construct it and evaluate it with my present phono part. With my rekindled curiosity in constructing electrical stuff, I used to be joyful to simply accept his invitation. The constructing course of and the outcomes had been as soon as once more nice, and since this equipment is of potential curiosity to anybody pondering of going vinyl, following is an in depth description of my expertise with the PP-Four.

Note, from the Muffsy web site:

The solely exceptions to the Creative Commons on muffsy.com is for just a few of my PCB designs, primarily variants of people who I am at present promoting. They are free for private or non-commercial use, however you can’t use them commercially with out my approval.

Getting began

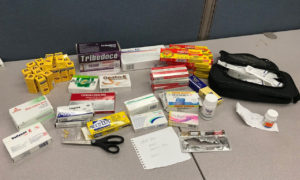

The picture under exhibits my desk as I’m on the point of begin the construct.

In entrance of my outdated Toshiba laptop computer (which is there to offer me entry to Muffsy’s construct directions), from left to proper are the case and energy provide (which have to be ordered from different suppliers), a flux pen (haven’t wanted this but), solder wick (ditto), the bundle wherein the equipment arrived (lined in cool stamps from far-off), the switches and connectors, the circuit boards, a bundle of DIP switches and stuff, one other bundle of capacitors and resistors and different stuff, my multimeter, and a hand-written stock of what’s within the packages.

Behind all that, to the precise of my laptop computer is the cellphone (unrelated), the Hakko soldering station and iron, a pleasant mild, solder, and a magnifying glass on a clamp stand. This is an outdated desk, so I don’t fear about marking it with dropped instruments, liquid solder, or different stuff. It’s additionally proper subsequent to a south-facing window and may be very well-lit, an essential consideration.

Time to get began!

First, the ability provide

The PPA-Four wants high-quality regulated ± 15V direct present energy to carry out at its finest. In my case, I selected to make use of the Muffsy energy provide equipment and a 16VAC wall wart really helpful on the Muffsy website.

The picture under exhibits the parts wanted for the ability provide:

In entrance, from left to proper—the filter capacitors (good Nichicon electrolytics!) and hookup wire, the resistors, diodes, bypass capacitors and terminal blocks, and the voltage regulator built-in circuits.

Above is the ability provide circuit board. The first step is to suit the diodes into the circuit board and solder them in. It can’t harm to say that diodes have to be oriented accurately; the diodes are marked and the circuit board is marked to match, as proven within the following picture:

Note that the diodes have a silver band on one edge, and the mounting spots on the board present the define of the diode with a black stripe at one finish. I take advantage of a pair of needle-nosed pliers to make good bends within the steel leads in order that the diodes match into the holes with out alignment issues. Once the leads are all by way of the board, I begin soldering. The picture under exhibits the board after I’ve soldered three of the eight diodes.

This is an efficient level to say just a few essential issues:

-

It’s worthwhile shopping for a good soldering iron, ideally temperature-controlled, and respectable solder (a really fantastic solder is finest for this sort of work); the soldering video referenced on the Muffsy website is enjoyable to look at and really helpful.

-

In my opinion, anybody who within reason dextrous and has respectable imaginative and prescient can do this sort of work. Yes, the builder should know what the parts are, what they do, and so forth, however between the Muffsy directions and all of the fantastic background info on the Web, this venture requires neither severe geekiness nor the help of a rocket scientist.

-

Patience and luxury and a well-lit workspace make an enormous distinction to the end result, when it comes to each the enjoyment of the construct and the standard of the end result.

Jumping forward just a few extra steps, right here is the board with all the resistors and diodes soldered in place:

Note that resistors don’t require a particular orientation. The colored stripes are a code that offers the worth, and I prefer to ensure that all of them learn the identical manner in order that I can test one final time to make sure I’ve obtained the precise resistors in the precise locations. So for instance, if we have a look at the light-blue resistor close to the highest heart of the picture, we see the stripes are orange, orange, black, brown, and brown, from prime to backside. Looking on the hyperlink famous above, we see this corresponds to 330 X 10¹ = 3300 ohms and the resistor tolerance is 1%. The equipment arrives with the resistors tagged with tape displaying their values, however as soon as the tape is gone, the one factor left is the colour code. The brown resistors oriented horizontally are 5% (the gold band to the precise) and they’re yellow, violet, gold, which corresponds to 47 X 10¯¹ = Four.7 ohms (5% resistors have one much less digit of precision of their worth).

The subsequent picture exhibits the board with the bypass capacitors, voltage regulators, and one filter capacitor mounted.

The bypass capacitors are the small golden blobs that say “100nF” beside them. The voltage regulators are standing up from the board with their steel warmth sink tabs seen; they have to be accurately oriented. The spherical black cylinder on the lower-left is the filter capacitor, and the grey stripe seen dealing with downward exhibits the required orientation.

It’s essential to get the orientations appropriate for these parts that require it. At finest the circuit gained’t work; at worst you would possibly destroy the parts. It’s price double-checking. Again, the directions are very clear, however however, I discover myself placing issues within the incorrect manner infrequently, and that second test has at all times discovered these issues (to this point).

The picture under exhibits the ultimate accomplished energy provide with all filter capacitors and the terminal block (for connecting to the preamplifier board) mounted:

This is an efficient place to emphasise that this wasn’t arduous and it didn’t take a substantial amount of time. Allowing for all of the checking and the photo-taking, it’s a few two-hour process, and for a really high-quality end result.

Next, the phono preamplifier

The phono preamplifier has a lot of resistors and fairly just a few capacitors, as proven within the picture under:

In this picture, the strips of tape holding resistors of the identical worth are seen, together with their labels. The golden blobs are once more bypass capacitors. The pink wafers are additionally capacitors that kind part of the compensation community used to regulate the output of the cartridge in order that the frequency response is flat. The black tubes with grey stripes are additionally capacitors, used to stop DC from showing on the output of the preamplifier. And after all, the circuit board is to the precise of the picture.

The picture under exhibits all of the resistors soldered onto the board:

This is an efficient level to say that it’s at all times worthwhile checking that each one parts are absolutely soldered to the board. I missed a few solder joints as I used to be soldering and seen them solely on a second inspection.

The picture under exhibits the board with just a few extra parts added:

The black squares are the carriers for the operational amplifiers that do the precise amplification on this circuit. It’s potential to solder the amplifiers on to the board, however it’s additionally good to have the ability to substitute different amplifiers relying on the appliance, and so they’re darned finicky to unsolder. The purple change blocks management the enter impedance and acquire of the circuit, permitting to be used with many alternative sorts of cartridges.

Putting all of it collectively

The subsequent picture exhibits the 2 accomplished boards—energy provide and preamplifier—earlier than connecting them and putting in the operational amplifiers.

I discover the final development step, which is connecting the boards to one another, to the enter and output connectors, and to the ability from the wall wart, to be probably the most troublesome. That hookup wire has a thoughts of its personal, and the shielded cable supplied may be very troublesome to strip. Patience and an excellent wire stripper are important right here.

Here is the completed amplifier in its case and prepared for power-up testing:

The boards slide into the case and the again plate attaches to the case with screws supplied with the equipment. At this level, earlier than putting in the operational amplifiers, I examined the voltage at varied factors to verify all was accurately put in and dealing correctly. The troubleshooting page explains how to do that (not that I used to be anticipating hassle, however it’s good to make sure).

The end result

Here I’m with my second piece of equipment from Muffsy, and I’m as impressed as I used to be the primary time. These are actually well-done—not simply the boards and supplies, however the great group of the web site. And the gadgets work exceptionally properly. I’m impressed with the sound high quality from each the pre-preamplifier and the preamplifier.

So, in case you have not too long ago acquired (or grow to be considering) a report participant however you don’t have any method to join it to the remainder of your gear—pc, powered audio system, headphone amplifier, or receiver—and are prepared to speculate a few of your personal time in constructing an answer, this can be a nice choice. And in the very best spirit of open supply, when you’d relatively hack your personal boards, casework, and energy from the designs on the Muffsy website, you’re free to take action.