Markian Hawryluk

[UPDATED on April 17]

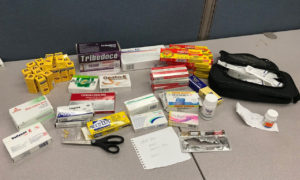

DENVER — For years, producers of ventilators and different medical gear have saved a decent grip on the flexibility of hospitals to service and restore these merchandise, prompting lawsuits and under-the-table sharing of restore manuals and software program passwords.

Now, within the midst of the COVID-19 pandemic, the necessity for product data to maintain ventilators up and operating is at an all-time excessive.

Modern ventilators are usually serviced both each six months or 2,000 hours of use and may final for 10 years if maintained correctly. But now almost each ventilator is being known as into near-constant service in scorching spots, with some pulled out of storage after eight years on the shelf. When any ventilator breaks down amid the surge of instances, ready two weeks for a restore can imply sufferers die.

While some producers have made restricted concessions to assist hospitals and third-party service suppliers preserve gear throughout the disaster, many biomedical gear technicians, recognized within the discipline as “biomeds,” are going through roadblocks in evaluating and servicing ventilators desperately wanted for affected person care.

“Manufacturers have been in more of a protective mode, making sure they’re protecting their market share and the quality of their services,” stated Ken Ottenberg, vp of medical gear administration for Denver-based service supplier HSS. “Saving lives and taking care of patients is what we’re trying to do. Are we not going to meet the demand at this time because of a business decision, instead of a quality-of-care decision?”

AdvaMed, a commerce group for medical system producers, has argued in opposition to permitting third-party servicers to work on complicated gear with out correct coaching and oversight, and maintains that even throughout the present disaster, there isn’t any proof of a scarcity of certified manufacturer-trained technicians.

“The bottom line is that medical technology companies or their designated representatives are best equipped to service their products and keep patients who use them safe,” stated AdvaMed spokesperson Jim Jeffries. “They are effectively serving the needs of patients and health care providers to respond both to the COVID-19 pandemic and other ongoing health care needs.”

Part of the equation is financial. Many producers add to their revenues by controlling the servicing and restore of the gear they promote. They prohibit entry to gear data to solely these technicians who full a producer’s coaching course. And as machines have change into extra computerized, corporations use software program locks to stop repairs with out permission.

“If you can’t get the access to the software, then all you have is a bunch of metal there,” stated Bill Bassuk, president and CEO of the College of Biomedical Equipment Technology in San Antonio. “If they sold the equipment and it belongs to the hospital, then whomever that hospital wants to work on that equipment should be allowed to work on it.”

Right To Repair

That’s prompted a “right to repair” motion for medical expertise, looking for to interrupt up the producers’ monopoly on service and restore. Similar battles have been fought over vehicles, farming gear and cellphones.

“When the only company to fix it is the company that made it, that’s another incentive for them to get you to buy a new one instead,” stated Nathan Proctor, director of the Right to Repair marketing campaign for the general public curiosity advocacy group U.S. PIRG.

So far, at the very least 20 states have thought of right-to-repair laws. Colorado was scheduled to vote on a invoice this yr, however the legislature was shut down early due to the pandemic.

Proctor argues that producers ought to enable entry to service data at the very least throughout the present disaster. Once the pandemic abates and lives are not at stake, the business might have a extra measured dialogue about the precise to restore.

Some producers have made allowances throughout the previous month as demand for ventilators and servicing spiked. Medtronic, for instance, launched the schematic designs for an older ventilator mannequin in order that new producers can check with a confirmed design.

But technicians stated they’re nonetheless having bother accessing service manuals for Medtronic’s top-of-the-line ventilators.

“They need to move from a service model to an information-sharing model,” Proctor stated. “There needs to be training, and there needs to be access to service information and passwords.”

In a press release emailed to Kaiser Health News, Medtronic spokesperson John Jordan stated the corporate gives service manuals to hospital biomeds to assist them with primary troubleshooting and testing when requested however, to this point, had obtained fewer than 10 requests.

“Currently, our hospital customers are more concerned about having or receiving a ventilator than servicing one,” Jordan stated. “Publishing service manuals broadly would not help increase the number of available ventilators.”

Manpower Issues

In Colorado, Ottenberg stated, one ventilator producer, which he declined to call, has simply two service technicians for the state.

“In any given normal month, those technicians can service all the equipment as needed for scheduled maintenance,” he stated. “Now we get into COVID, there’s no way.”

Marty Fulkerson, director of operations for scientific engineering on the Centura Health system, which incorporates 17 hospitals in Colorado and Kansas, stated that when one producer’s service technician in Colorado was quarantined for 2 weeks after a COVID-19 publicity, the corporate pulled senior officers with restore expertise out from behind their desks to satisfy the demand.

Third-party service suppliers say producers could haven’t any alternative however to loosen their restrictions, as they can not deal with the elevated want for service.

Ottenberg stated the business has had a scarcity of technicians for the previous two years at the very least, and with the pandemic, most of the technical colleges have stopped coaching new biomeds. Now, biomeds say, service calls are scheduled out at the very least one to 2 weeks, leaving some gear offline.

“It’s insane. It’s unacceptable if they can’t get out there for one to two weeks,” Bassuk stated. “They’re trying to recruit enough to have a proper workforce, but they’re pretty much going to be overworked now.”

While in-house and third-party biomeds are prepared to tackle the additional work, they haven’t been capable of attend in-person coaching periods due to restrictions on journey. Some producers are holding on-line coaching to assist biomeds educated on one mannequin of ventilator troubleshoot different gear from the identical firm.

Burning The Midnight Oil

Jean Roberts, a biomed with the University of Vermont Medical Center, has been working six to seven days every week to maximise the provision of his facility’s ventilators.

“Thankfully, we biomeds are pack rats by nature,” he stated. “Anything not in use, but not defective either, we scurried away to a warehouse for times like this.”

During the disaster, he has pulled 14 older ventilators out of storage and labored to exchange the batteries and carry out required upkeep. He then needed to discover the disposable elements for these ventilators and prepare staffers who had by no means used these old-school machines earlier than.

“They’re used to a touchscreen,” he stated.

The University of Vermont hospital had greater than 100 ventilators scheduled for preventive upkeep in April. Roberts and one other senior biomed put different duties apart in early March to work solely on ventilator upkeep, realizing a surge in demand was possible coming.

But discovering alternative elements has been a problem.

“We’re getting a lot of partial orders where we get all but one part we need,” he stated.

The arrival of latest ventilators from different hospitals or from a stockpile can imply biomeds have to stand up to hurry shortly on unfamiliar gear. Roberts stated that when Vermont ordered new ventilators, three of the 4 fashions out there had been ones the University of Vermont hospital had by no means used.

Some of the stockpiled ventilators haven’t been used for six to eight years and require fast upkeep earlier than they are often pressed into service.

Seeking Help

When producers are unwilling to share upkeep procedures, biomeds typically flip to on-line boards, comparable to MedWrench or iFixit, for assist. The boards are inundated with requests for service manuals or software program passwords for ventilators from technicians everywhere in the world.

Frank’s Hospital Workshop, a web site run by a German biomed residing in Tanzania, created a website with manuals for older medical gear that finds its technique to hospitals in creating areas. Those hospitals have little alternative however to attempt to make repairs on their very own and eke out further years of life from the getting old gear. Still, producers have prohibited the obtain of some service manuals on the location, arguing that the gear can not be safely repaired.

“For a premature child, the downside of it not working is a lot bigger than the repair quality,” Proctor stated. “It’s not that complicated a device.”

Roberts has tried to assist different biomeds posting on boards by directing them to producer web sites, however he stated he received’t go as far as to share service manuals or passcodes, even throughout the present disaster.

“If you weren’t doing the maintenance to begin with,” Roberts stated, “now’s not the time to learn.”

These unprecedented situations, nonetheless, could also be biomeds’ time to shine.

“The work that biomeds do has been historically largely confined to the dark corners of the basement or the lower recesses of the hospitals,” stated Richard Gonzales, director of the College of Biomedical Equipment Technology. “But they do truly keep the lights on in the hospital.”

[Correction: This story was final revised at 10:10 a.m. ET on April 17 to right the standing of “right to repair” laws. At least 20 states have thought of such laws.]

Kaiser Health News (KHN) is a nationwide well being coverage information service. It is an editorially unbiased program of the Henry J. Kaiser Family Foundation which isn’t affiliated with Kaiser Permanente.