The downside with vitality prices is that most individuals do not take into consideration them. They simply have a look at their total invoice with out contemplating how the vitality was used. By monitoring and measuring vitality use via sensors in very particular areas, vitality waste will be made clear and diminished.

That’s the premise of the e book Reinventing Fire: Bold Business Solutions for the New Energy Era, which gives strategies to remove the usage of fossil fuels by 2050 via vitality waste discount. It’s additionally the premise of a narrative I started in an earlier article about two retired utilities salespeople-turned-consultants who began an open group neighborhood to scale back vitality waste of their area, which they name the “Reinventing Fire Community.” Their work depends upon the open organization principles of Community, Transparency, Collaboration, Inclusivity, and Adaptability.

In that article, I talked about actions certainly one of my imaginary consultants really useful for dwelling and business constructing homeowners. In this text, I focus on the opposite fictional marketing consultant, who bought electrical energy to factories.

It could also be stunning how a lot vitality is wasted in factories. The reality is, there aren’t sufficient vitality specialists obtainable proper now, and most manufacturing managers have their consideration on different issues, significantly manufacturing quantity. Too many high managers have a look at gross sales, revenue margins, and gross revenue and miss “boring” bills. In addition, small financial savings are exhausting to see till they’re multiplied a whole lot of instances.

In addition, most operations managers have a look at every course of individually and individually. They cannot see the general vitality waste image till it is identified. This is the place transparency and collaboration between individuals in all plant processes are important. There may be numerous duplications of processes the place cooperation could possibly be very helpful. Real rewards could take 3-5 years to materialize, and sadly, many individuals solely have a look at short-term positive aspects.

Factory vitality marketing consultant

In this hypothetical case examine, the manufacturing facility vitality marketing consultant goes to factories, beginning with their earlier electrical energy customers. They provide options on the right way to cut back yearly vitality bills by a minimum of 10-50%. If tools funding is required, the marketing consultant guarantees that the tools pays for itself in 3-5 years of financial savings.

The marketing consultant units the next situations for working collectively:

- The manufacturing facility operator have to be as clear as potential about present vitality use and bills.

- The marketing consultant is not going to give anybody this data besides trusted companions they’re working with to generate the easiest proposals.

- There is not any cost for the consulting, as they solely need to cut back vitality use locally, and at this stage the consultants do not know the way precious they are going to be.

- The marketing consultant would really like a efficiency report and a common testimonial letter on the finish of two years explaining how a lot the vitality consumer’s invoice has been diminished.

Industrial vitality use

How can this marketing consultant use all of the ideas of Community, Transparency, Collaboration, Inclusion, and Adaptability?

First, the manufacturing facility vitality marketing consultant makes an appointment with their most trusted electricity-using manufacturing firm and explains that they can assist the corporate lower your expenses, with a goal of saving 27% of major vitality by 2050 whereas sustaining present manufacturing ranges. This will save the corporate cash and cut back the influence of unstable worth adjustments or energy failures.

The marketing consultant explains the chart beneath to offer perspective on the place vitality waste will be averted.

From Reinventing Fire, by Amory Lovins (Ron McFarland, CC BY-SA 4.0)

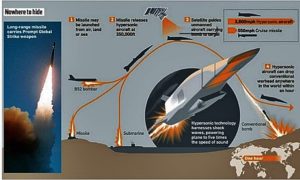

In manufacturing, 40% of the first vitality (vitality that comes immediately from the supply, equivalent to coal, fuel, oil, and so forth) is used for heating, and one other 40% is used for rotating shafts on machines. The remaining 20% goes to a variety of processes like smelting, reducing, grinding, boring, lighting, and house conditioning. Those are the areas the marketing consultant needs to discover.

Secondary vitality is transformed to electrical energy and delivered. There is loss throughout this conversion, as illustrated within the bar chart beneath. Electricity-system losses use practically as a lot major vitality as course of warmth does.

From Reinventing Fire, by Amory Lovins (Ron McFarland, CC BY-SA 4.0)

The marketing consultant explains that there are two most important areas to have a look at concerning energy-use discount: warmth and stress. Where is extraordinarily excessive temperature utilized within the manufacturing course of? Where is excessive stress utilized? Also, how can waste in a single course of turn out to be a uncooked materials enter for one more? This consists of extra warmth and extra stress. Sometimes these two are produced and used collectively, known as mixed warmth and energy (CHP). Those two can generally generate electrical energy from major excessive warmth and stress and different instances from leftover decrease warmth and stress from a given course of.

Reducing vitality consumption in factories

The marketing consultant explains 4 areas the place vitality is used and will be diminished in any manufacturing facility:

- Level 1: Reduce manufacturing processing vitality use. Sometimes this may be completed through the use of sensors and controls to cease tools from working when not wanted. Fine-tuning stress controls and giving notifications when upkeep is required to keep up supreme efficiency are different technique of decreasing vitality use at this degree.

- Level 2: Reduce vitality supply losses. This will be achieved by insulating pipes, sustaining steam traps and air filters, and so forth. Changing wiring may also cut back electrical vitality loss. Old wires had been developed solely to stop fires, however new variations are designed to save lots of vitality, reducing waste considerably. The marketing consultant mentions that they need to evaluation the age and vitality supply effectivity of all wiring. Air compressors could possibly be checked for energy-wasting leaks. Just making these adjustments may pay for itself in six months.

- Level 3: Get higher at producing in-house vitality via higher gadgets. Motors run drill presses, chillers, grinders, mixers, and blowers. The value of working them for just a few weeks could possibly be the identical as completely changing the facility motor itself. The marketing consultant asks a number of questions: When are these motors working? Are they the appropriate dimension and specs for his or her use proper now? Are there gadgets on the machines that measure vitality use? Can variable-speed management be put in to scale back wasted RPMs? What is the age of the motors? These questions additionally apply to pumps, followers, furnaces, compressors, chillers, blowers, and boilers. The marketing consultant explains that in most factories at the moment, nearly all boilers lack good controls that cut back start-up and shutdown vitality waste.

- Level 4: Put vitality waste to make use of. Waste warmth and extra stress will be both ineffective or a precious vitality supply. Repeated cycles of heating and cooling take vitality. In most factories, gas is transformed one-third into electrical energy and two-thirds into warmth. That warmth fairly often is thrown away. The quantity of vitality loss in US factories is the same as the quantity of vitality Japan makes use of for all the pieces. That is a large waste. Could that warmth be transported to a different course of? The marketing consultant might need to incorporate a specialist from the Rocky Mountain Institute to handle this matter.

The marketing consultant provides that the 4 ranges above can play off one another. Super-efficient boilers, ultrasound-aided drying methods, and different energy-saving gadgets are actually obtainable. The Industrial Assessment Centers from the US Department of Energy is a good supply. There, US corporations can be taught the place to scale back vitality totally free. The US Energy Information System may be useful.

Another factor to have a look at is industrial waste. Could what they throw away be transformed right into a byproduct?

[ Related read 4 reasons IT leaders should champion sustainability ]

Analyzing waste

When analyzing vitality waste, begin the place the vitality is utilized and work backward to the facility technology location. Reinventing Fire offers an instance of a datacenter within the diagram beneath:

From Reinventing Fire, by Amory Lovins (Ron McFarland, CC BY-SA 4.0)

Notice it begins on the left with the vitality wanted for computing, then displays the method of vitality loss via the datacenter, server, functions, and enterprise course of. Is that computation wanted? Is the software program environment friendly? Next, have a look at the IT tools. Is it appropriate for that kind of labor? Next, have a look at the cooling and energy provide. Is it applicable? This identical kind of questioning ought to be finished for every course of within the manufacturing facility operations supervisor’s facility.

The marketing consultant mentions that beginning on the use level can be useful for piping and air/fluid movement. Generally, smaller pipes require extra vitality to pump fluid/air/fuel via them and require bigger pumps. This is true for curves within the piping as effectively. The much less the curve angle, the higher. First, design the piping dimension and curves, then choose the pump required. The fatter and straighter, the smaller the pump requirement. Doing this proper saves over half the vitality required.

Many factories had been designed when gas was low-cost, so these value financial savings weren’t thought of. The marketing consultant offers the beneath instance:

From Reinventing Fire, by Amory Lovins (Ron McFarland, CC BY-SA 4.0)

Notice that almost all vitality is misplaced proper within the energy station the place the electrical energy is generated. Then, there’s loss in getting the electrical energy to the situation, to function the motor, to run the drivetrain, pump and values and eventually, the fluid going via the pipes. All these losses ought to be checked out. Therefore, the marketing consultant asks the operations supervisor to elucidate all manufacturing facility piping and air/fluid movement methods.

Assume they discover areas that waste plenty of vitality and retrofit the complete movement system. What concerning the dimension of the pumping tools? Is it now too massive for the method? Equipment is normally bought to have the capability to provide most demand. When that most demand is not wanted, the motor must also be downsized, even when it has life in it. Motor selection, life, sizing, controls, upkeep, and related electrical and mechanical components work together intricately. Now, with a discount within the requirement, the motors could possibly be changed with extra environment friendly and smaller ones.

Over and above diminished pumping demand, tools refurbishing can generally pay for itself in lower than a couple of years. For instance, bearing high quality has improved through the years. That alone may generate vital financial savings.

The marketing consultant asks about any furnaces within the manufacturing facility, a significant vitality consumer. They point out that reverberatory furnaces to soften aluminum will be changed by electrical heaters with ceramic coatings. This known as isothermal melting, which saves vitality and ground house. Solar heating is one other main energy supply for business, with falling costs and better effectivity.

Production tools lifecycle

Items used for manufacturing undergo a lifecycle, and outdated tools needn’t be thrown away. Before they’re declared as a complete waste, sources could possibly be:

- Recovered (introduced out of retirement and used once more)

- Reused (moved from a most important course of to a backup course of)

- Repaired (simply fastened with upgraded elements)

- Remanufactured (reshape for continued use)

- Recycled (break down uncooked supplies for added use)

The marketing consultant asks concerning the age and lifetime of all of the manufacturing tools. How a few years of life does each bit of kit have? What is the recycling program?

Energy sourcing

Whether for buildings, houses, or factories, vitality sourcing will change drastically from centralized provide to distributed provide within the years forward. The marketing consultant recommends they appear over the complete manufacturing facility and ask the place photo voltaic panels and mini wind-power mills may be put in. Additionally, they ask about any neighborhood vitality grid tasks within the area.

Furthermore, they ask concerning the car fleet (together with supply vans and forklifts) and internal-combustion-powered mills, cranes, and any material-moving tools. Could they be powered by electrical energy? If so, they may be a possible energy supply as effectively.

Company incentives

After reviewing all these energy-saving measures, the marketing consultant mentions that taking a look at vitality waste is not nearly processes. It’s about worker consideration too. Issues of vitality waste, transparency, collaboration, and adaptation have to be inclusive to all front-line staff. They ought to be included and inspired to kind their very own “Reinventing Fire Communities” to allow them to see waste firsthand. The marketing consultant mentions that many corporations have drawn staff’ consideration to vitality waste by introducing competitions between divisions, evaluating waste discount percentages from their present vitality consumption benchmarks. A variety of incentives, raffles, video games, contests, and awards can might also appeal to worker curiosity.

Community growth

To guarantee experience develops as rapidly and effectively as potential, the manufacturing facility vitality effectivity marketing consultant and the constructing marketing consultant within the earlier article focus on and collaborate on how their conferences with vitality customers went. They additionally stored the Rocky Mountain Institute within the loop. That approach, everybody can be taught from one another’s experiences. For complete transparency, their assembly reporting system is interconnected.

With many successes in decreasing vitality waste in factories, buildings, and houses, they gathered many testimonial letters on how they’ve helped particular person households and firms. With these letters and experiences, the 2 fictional consultants determined to fastidiously increase their neighborhood and objective to seek the advice of for warehouses, shops, purchasing malls, industrial park builders and operators (not concerned in manufacturing), and distribution facilities. For this growth, they began searching for consultants as devoted to decreasing vitality waste as they’re.

Those had been equally profitable, so that they mentioned whether or not these tasks could possibly be monetized and opened discussions of building a start-up firm within the space.

This has been a theoretical case examine largely knowledgeable by Reinventing Fire: Bold Business Solutions for the New Energy Era. But you may see the important position open group ideas have performed on this situation. Energy waste is diminished. Companies and households save a substantial amount of cash. Lifestyles haven’t modified, however high quality of life has improved. And lastly, a probably viable enterprise mannequin is created that would unfold each nationally and probably globally.