After unanimously voting to suggest a miraculous hepatitis C drug for approval in 2013, a panel of consultants advising the Food and Drug Administration gushed about what they’d completed.

“I voted ‘yes’ because, quite simply, this is a game changer,” National Institutes of Health hepatologist Dr. Marc Ghany stated of Sovaldi, Gilead Science’s new tablet designed to remedy most instances of hepatitis C inside 12 weeks.

Dr. Lawrence Friedman, a professor at Harvard Medical School, known as it his “favorite vote” as an FDA reviewer, in response to the transcript.

What the panelists didn’t know was that the FDA’s drug high quality inspectors had advisable in opposition to approval.

They issued a scathing 15-item disciplinary report after discovering a number of violations at Gilead’s fundamental U.S. drug testing laboratory, down the street from its headquarters in Foster City, Calif. Their findings criticized points of the standard management course of from begin to end: Samples have been improperly saved and catalogued; failures weren’t adequately reviewed; and outcomes have been susceptible to tampering that would cover issues.

Gilead Foster City doesn’t manufacture medication. Its job is to check samples from drug batches to make sure the capsules don’t crumble or include mildew, glass or micro organism, or have too little of an energetic antiviral ingredient.

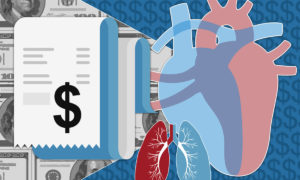

Recent information studies have targeted public consideration on poor high quality management and contamination within the manufacturing of low cost generic medication, significantly these made abroad. But even among the latest, costliest brand-name medicines have been stricken by high quality and security considerations throughout manufacturing, a Kaiser Health News evaluation exhibits.

More disturbing, even when FDA inspectors flagged the potential hazard and raised pink flags internally, these issues have been resolved with the company in secret ― and not using a follow-up inspection ― and the medication have been accepted on the market.

Erin Fox, who purchases medicines for University of Utah Health hospitals, stated she was shocked to listen to from KHN about manufacturing issues uncovered by authorities on the amenities that make brand-name merchandise. “Either you’re following the rules or you’re not following the rules,” Fox stated. “Maybe it’s just as bad for branded drugs.”

The stress to get modern medication like Sovaldi into use is appreciable, each as a result of they provide new remedies for determined sufferers and since the medicines are extremely worthwhile.

Against that backdrop, the FDA has repeatedly discovered a option to approve brand-name medication regardless of security considerations at manufacturing amenities that had prompted inspectors to push to reject these medication’ approval, an ongoing KHN investigation exhibits. This occurred in 2018 with medication for most cancers, migraines, HIV and a uncommon illness, and 10 different instances lately, federal data present. In such instances, how these points have been mentioned, negotiated and in the end resolved just isn’t public file.

For instance, inspectors discovered that amenities making immunotherapies and migraine remedies didn’t comply with up when drug merchandise confirmed proof of micro organism, glass or different contaminants. At a Chinese plant making the brand new HIV drug Trogarzo, staff dismissed “black residue” discovered to be “non-dissolvable metal oxides,” assuming it “did not pose a significant risk,” federal data present.

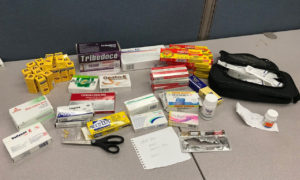

Without a follow-up inspection to verify drugmakers corrected the issues inspectors discovered, these medicines ultimately have been accepted on the market, and at checklist costs as excessive as $189,000 a month for a mean affected person, in response to well being knowledge agency Connecture. The most cancers drug Lutathera was initially rejected over manufacturing issues at three crops however was accepted a 12 months later and not using a contemporary inspection and was priced at $57,000 per vial.

John Avellanet, a marketing consultant on FDA compliance, stated knowledge integrity issues, like these at Gilead’s lab in Foster City, ought to have sparked additional investigation, as a result of they elevate the opportunity of “deeper issues.”

Dr. Janet Woodcock, the director of the FDA’s Center for Drug Evaluation and Research, stated an inspector’s advice to withhold approval might be “dealt with” and not using a follow-up. Woodcock stated the company can’t touch upon specifics, and firms are reluctant to debate them as a result of the main points of the decision are protected as a company commerce secret.

“That doesn’t mean that there’s anything wrong with the drug,” Woodcock stated.

Dinesh Thakur, a former drug-quality worker turned whistleblower, known as the secrecy a “red flag.” A follow-up inspection is essential, he stated: “I’ve seen many times paper commitments are made but never followed through.”

What worries Fox is defective drug may get by and no person would know.

“In general, very few people suspect that their medicine is the problem or their medicine is not working,” Fox stated. “Unless you see black shavings or something horrible in the product itself, the drug is almost the last thing that would be suspect.”

The Market Beckons

If the FDA finds issues at preapproval inspections for generics, the company is prone to deny approval and delay the drug’s launch till the following 12 months’s overview cycle, in response to trade and company consultants.

In reality, simply 12% of generics have been accepted the primary time their sponsors submitted purposes from 2015 by 2017.

The calculus seems totally different for heralded new therapies like Sovaldi. In 2018, 95% of novel drugs ― the latest of the brand new ― have been accepted on the primary attempt, the FDA stated.

Woodcock stated the company has “the same standards for all drugs,” however she emphasised that most of the manufacturing points “are somewhat subjective.”

For new brand-name medication, she stated, the FDA “will work very closely with the company to … bring the manufacturing up to snuff.”

The producer submits written responses and commits to resolve high quality considerations, however the particulars are saved confidential.

An estimated 2.4 million Americans have hepatitis C and, earlier than Sovaldi, therapy got here with depressing unintended effects and a robust likelihood it wouldn’t work. Sovaldi promised as much as a 90% cure rate, although it got here with an eye-popping $84,000 price ticket for a 12-week course, placing it out of attain for many sufferers and well being care techniques.

But company stress to get such therapies into the marketplace can be appreciable.

Pharmaceutical corporations pay hefty charges for FDA overview and foyer the company to hurry merchandise to market. For Gilead, time misplaced is cash.

“If approval of sofosbuvir were delayed, our anticipated revenues and our stock price would be adversely affected,” Gilead wrote in an SEC document filed Oct. 31, 2013, utilizing the generic identify for Sovaldi.

Since its debut in 2013, Sovaldi has been extensively criticized for its value however acknowledged as a medical breakthrough. Gilead has by no means recalled it.

However, a whole bunch of sufferers who’ve taken the drug have voluntarily reported most cancers or different problems to the FDA’s “adverse event” reporting database, together with considerations that the therapy doesn’t all the time work. One in 5 Sovaldi sufferers and well being care professionals who reported severe issues to federal regulators stated the drug didn’t remedy the sufferers’ hepatitis C.

“The FDA approved these products after a rigorous inspection process, and we are confident in the quality/compliance of these products,” Gilead spokeswoman Sonia Choi stated.

Problems at Foster City

Gilead’s Foster City facility has been cited for an array of issues over time. In 2012, FDA inspectors stated the ability had did not correctly overview how the HIV medication Truvada and Atripla grew to become contaminated with “blue glass” particles; a few of that tainted batch was distributed. The firm “made no attempt to recover” the contaminated medication, in response to FDA inspection data.

Gilead had simply filed its software for Sovaldi’s approval when FDA inspectors arrived at Foster City for an unrelated inspection in April 2013. Inspectors slapped the ability with 9 violations in what’s known as a 483 doc and stated that the reliability of the positioning’s strategies for testing issues like purity have been unproven and that its data have been incomplete and disorganized, in response to FDA inspection paperwork.

As a outcome, the FDA initially rejected two HIV medication, Vitekta and Tybost. Gilead needed to resubmit these purposes, and it might take 18 months earlier than the FDA accepted them in late 2014.

On Sept. 19, 2013, FDA officers met to debate Sovaldi with Woodcock, company data present. Meeting minutes present inspectors advisable hitting Gilead Foster City with a proper warning letter based mostly on the April inspection. (A warning letter is a disciplinary motion from the FDA that sometimes features a risk to withhold new approvals or place a international facility on import alert and refuse to simply accept its merchandise on the market within the U.S.)

At the identical assembly, FDA inspectors stated their advice to approve Sovaldi can be “based on” eradicating an unnamed drug ingredient producer from the applying and “a determination that Gilead Foster City has an acceptable cGMP [current good manufacturing practices] status.”

Records present the FDA didn’t subject a warning letter or in any other case delay the approval course of when Foster City failed its inspection.

Instead, the Sovaldi preapproval inspection began 4 days later and lasted two weeks. At the tip, inspectors issued Foster City one other 483, this time with 15 violations, formally outlining issues and requiring a written plan to repair them. Inspectors stated they couldn’t suggest Sovaldi’s approval.

FDA officers gave Gilead two choices throughout an Oct. 29 teleconference: Remove Foster City, a “major testing site” for Sovaldi, from the applying, and use a third-party contractor as a substitute; or use Foster City however rent one other agency to observe the positioning and log off on its testing work.

Gilead was optimistic. “Based on recent communications with the FDA, we do not expect these [inspection] observations to delay approval of sofosbuvir,” the corporate stated in its Oct. 31 SEC submitting.

Gilead selected to interchange the Foster City plant with a contract testing web site, federal data present. By December, Sovaldi was accepted for distribution, and the corporate quickly introduced its $1,000-per-pill price ticket.

Not Just Generics

Recent media studies, and the continued recall of the extensively used blood stress medication valsartan, have led customers ― and members of Congress ― to query whether or not generics are manufactured safely. Valsartan capsules made in China and India have been discovered to include cancer-causing impurities.

Branded-drug high quality, largely, has been spared from congressional scrutiny. But many factories ― abroad and within the U.S. ― make branded and generic medication.

In January 2018, FDA inspectors hit a Korean manufacturing plant that makes Ajovy, a migraine drug, with a warning letter. With the issues nonetheless unresolved in April, an company reviewer advisable withholding approval. When they returned in July, inspectors needed to present the plant the worst attainable classification: “Official Actions Indicated.” Among different issues, inspectors discovered that cup vials typically broke throughout the manufacturing course of and that the ability lacked protocols to forestall the particles from moving into drug merchandise. The FDA’s Office of Manufacturing Quality ultimately downgraded the inspection to only “Voluntary Actions Indicated.”

The drug was accepted in September 2018 and priced at $690 a month. FDA data point out no additional disciplinary motion was taken. Teva, the maker of Ajovy, didn’t reply to requests for remark.

Similarly, when FDA inspectors visited a contract manufacturing facility in Indiana used to make Revcovi, which treats an autoimmune illness, they famous redacted drug lot had failed a sterility check as a result of the vials examined optimistic for a bacterium known as Delftia acidovorans, which might be detrimental even in folks with wholesome immune techniques, studies show. But the drug-filling machine stayed in use after the contaminant was found, the FDA decided. Inspectors advisable withholding approval.

The drug was accepted in October 2018 even after one other inspection turned up issues, with an inventory value of $95,000 to $189,000 per thirty days for a mean affected person, in response to well being care knowledge agency Connecture.

Revcovi’s producer, Leadiant Biosciences, stated by an outdoor public relations agency that its contract producer’s written responses to the FDA observations have been thought-about “adequate” by two FDA workplaces, including, “We do not have any more information to share with you at this time as pharmaceutical manufacturing processes are confidential.”

Problems with medication can take years to find ― after which solely after sufferers are injured. So, many well being researchers say, extra warning is warranted.

“They’re doing so few of these [FDA] inspections pre-market,” stated Diana Zuckerman, president of the nonprofit National Center for Health Research. “The least they can do is listen to the ones they’re doing.”